In industries requiring precision magnetic material cutting, traditional methods like laser or waterjet cutting may not always deliver the desired accuracy, especially for brittle or high-performance magnets like NdFeB (neodymium magnets) and ferrite magnets. This is where diamond wire saw cutting machines excel, offering unparalleled precision and minimal material loss.

At Ensoll, we specialize in advanced magnetic material processing using diamond wire saw cutting technology, ensuring clean cuts, reduced chipping, and superior edge quality for various industrial applications.

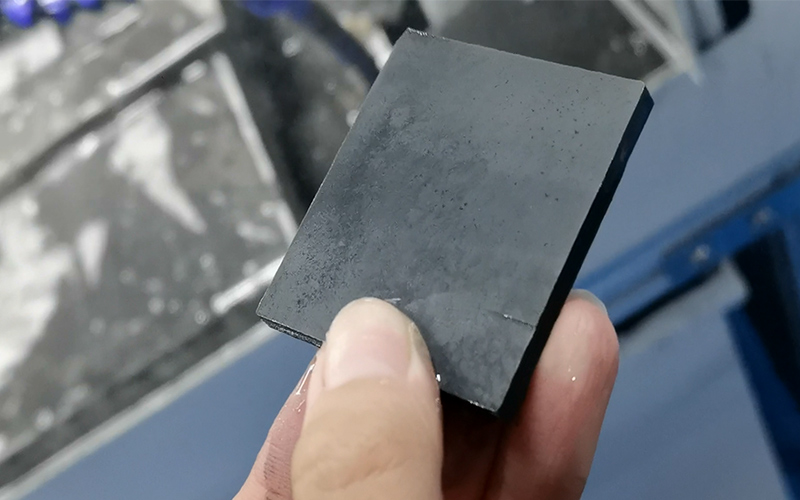

Unlike conventional magnet steel processing methods, a diamond wire saw cutting machine uses a thin, diamond-coated wire to make smooth, burr-free cuts. This is ideal for:

– NdFeB cutting (neodymium magnets)

– Ferrite cutting (ceramic magnets)

– Permanent magnet cutting (AlNiCo, SmCo)

The process minimizes material waste and maintains tight tolerances (±0.02mm), crucial for applications in motors, sensors, and medical devices.

Traditional magnetic material cutting methods (like laser or abrasive cutting) generate heat, which can weaken magnetic properties. Our diamond wire saw operates at low temperatures, preventing thermal damage and preserving magnet performance.

Materials like NdFeB magnets are prone to cracking under mechanical stress. The diamond wire saw applies uniform pressure, reducing micro-cracks and ensuring a clean cut without structural damage.

– Faster than traditional grinding methods

– Lower kerf loss (less material wasted)

– Longer tool life (diamond-coated wire lasts longer than abrasive blades)

Our diamond wire saw cutting machine is widely used in industries requiring precision magnet cutting, including:

– Advanced Diamond Wire Saw Technology – For the cleanest cuts in magnetic material processing.

– Custom Solutions – Tailored cutting services for NdFeB, ferrite, and other permanent magnets.

– Fast Turnaround and Competitive Pricing – Optimized for industrial-scale production.

For industries demanding precision magnetic material cutting, diamond wire saw cutting machines offer unmatched accuracy, efficiency, and material preservation. Whether you need NdFeB cutting, ferrite cutting, or custom magnet steel processing, our technology ensures superior results with minimal waste.

Contact us today to discuss your magnetic material cutting needs and discover how our diamond wire saw solutions can enhance your production process!

If you have any question, please contact us