Optical glass machining is a specialized field that combines precision engineering with material science to create components for advanced optical systems. From Schott optical glass cutting to Corning Gorilla Glass wire cutting, manufacturers employ various techniques to shape these delicate materials while maintaining their unique optical properties.

– Fundamental properties of different optical glass types

– Precision machining techniques including diamond wire saw for glass cutting

– Specialized applications from camera lens optical glass to infrared optical glass

– Comparative analysis of materials like flint glass for optics and phosphate laser glass

Types of Optical Glass

– High refractive index

– Used in prism and lens systems

– Requires careful machining due to softness

– Excellent energy storage capacity

– Critical for high-power laser systems

– Sensitive to thermal stress during cutting

– Exceptional thermal stability

– Low thermal expansion coefficient

– Ideal for UV-transmitting applications

– Specialized compositions for IR transmission

– Requires contamination-free machining

Precision Machining Techniques

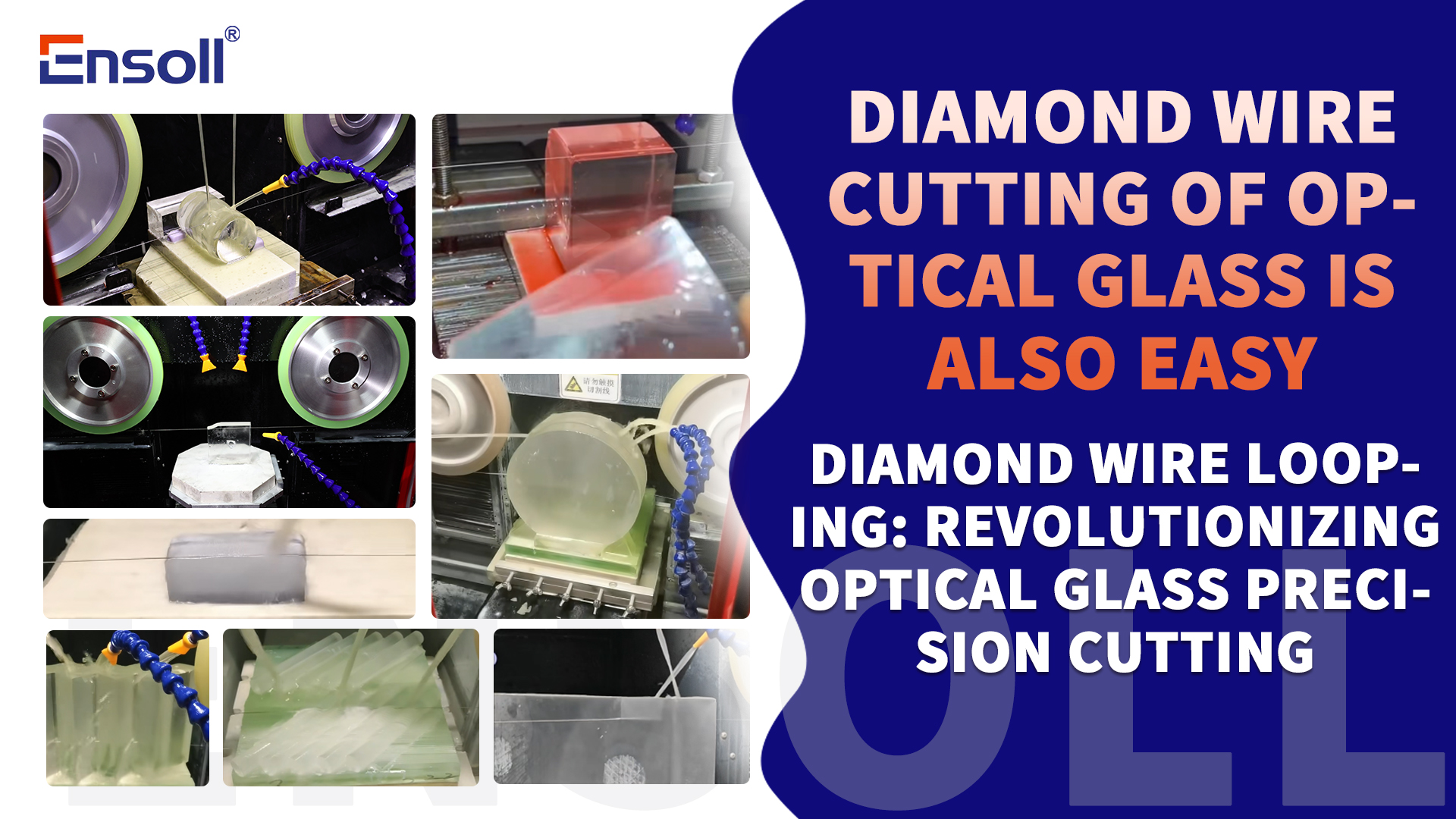

The diamond wire saw for glass method has revolutionized optical glass machining with:

– Unmatched Precision: Capable of achieving tolerances within ±0.01mm

– Material Efficiency: Minimal kerf loss compared to traditional methods

– Versatility: Processes everything from microscope slide glass to thick OHARA glass precision machining blanks

Application Example:

For Schott optical glass cutting, the diamond wire saw produces stress-free edges critical for high-performance optics.

– Non-contact process ideal for delicate materials

– Particularly effective for UV-transmitting glass

– Limited by thermal effects on some glass types

– Combines abrasive slurry with ultrasonic vibrations

– Excellent for intricate shapes in fused silica optical glass

– Slower process compared to diamond wire cutting

Camera Lens Optical Glass Production

Modern camera lens optical glass manufacturing requires:

– Multi-axis diamond wire saw cutting for aspheric surfaces

– Precision polishing after machining

– Strict cleanliness protocols

Corning Gorilla Glass wire cutting presents unique challenges:

– High-speed diamond wire saws prevent edge chipping

– Special tensioning systems for thin glass

– Automated inspection systems

Scientific and Medical Optics

– Mass production using automated diamond wire saws

– Edge quality critical for biological applications

– Specialized cutting fluids prevent contamination

– Coolant-free diamond wire options available

Japanese OHARA glass precision machining demands:

– Custom diamond wire formulations

– Temperature-controlled environments

– Vibration-dampened equipment

Key requirements for phosphate laser glass:

– Low-stress mounting during cutting

– Post-machining stress relief processes

– Cleanroom processing often required

Critical inspection parameters include:

– Surface roughness measurements

– Edge chip detection

– Wavefront distortion analysis

– Stress birefringence testing

Advanced metrology tools like:

– White light interferometers

– Laser scanners

– Automated optical inspection systems

– Machine learning for cutting parameter adjustment

– Predictive maintenance for diamond wire saws

– Combining diamond wire cutting with laser processing

– In-line metrology integration

– Diamond wire recycling programs

– Water-free cutting alternatives

From Schott optical glass cutting to infrared optical glass component production, modern machining techniques like the diamond wire saw for glass have transformed optical manufacturing. Understanding material properties and selecting the appropriate machining method is crucial whether working with:

– Flint glass for optics in traditional lenses

If you have any question, please contact us