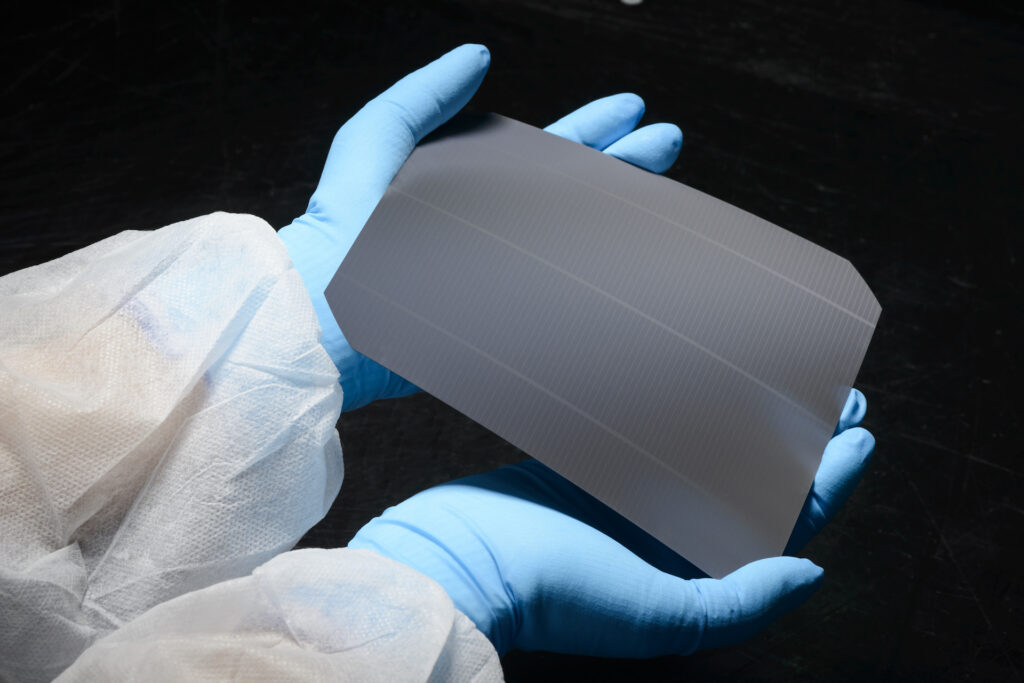

The solar industry relies on high-quality silicon wafers to produce efficient photovoltaic (PV) cells. One of the most critical steps in solar manufacturing is wafer slicing—the process of cutting silicon ingots into thin wafers ready for solar cell production.

Among various cutting methods, diamond wire saw cutting machines have emerged as the industry standard due to their precision, efficiency, and cost-effectiveness. This blog explores wafer slicing technologies, focusing on why diamond wire saw cutting dominates the market and how it enhances solar cell performance.

Silicon wafers are the foundation of solar cells, and their quality directly impacts:

✔ Cell efficiency – Poor cutting can introduce micro-cracks, reducing energy conversion.

✔ Material yield – Thinner kerf (cut width) means less silicon waste.

✔ Production costs – Faster, more precise cutting lowers manufacturing expenses.

Traditional wafer slicing methods, such as slurry-based wire sawing, are being replaced by diamond wire saw cutting machines, which offer superior performance.

– Uses a steel wire + abrasive slurry (silicon carbide) to cut silicon.

– Disadvantages:

– Slow cutting speed (~0.5–1 m/s)

– High kerf loss (~180–250 µm)

– Slurry contamination requires extensive cleaning

– Higher breakage rates

– Uses a high-energy laser to slice wafers.

– Advantages:

– Ultra-thin kerf (~30–50 µm)

– No mechanical stress

– Disadvantages:

– Heat-affected zone (HAZ) damages silicon

– High equipment cost

– Not ideal for thick wafers (>200 µm)

– Uses a steel wire coated with diamond particles for cutting.

– Why it’s the best choice today:

✅ Faster cutting (10–25 m/s)

✅ Lower kerf loss (~100–150 µm)

✅ No slurry = cleaner process

✅ Higher wafer quality (fewer micro-cracks)

✅ Cost-effective for mass production

– Kerf loss is 30–50% lower than slurry-based sawing.

– More wafers per ingot = lower cost per watt.

– Surface roughness <1 µm (vs. 5–10 µm with slurry saws).

– Fewer micro-cracks → higher cell efficiency (up to 0.5% gain).

– Processes 2,000+ wafers per hour (vs. 500–800 with slurry saws).

– 50% faster than traditional methods.

– No slurry waste = easier recycling & lower disposal costs.

– 50% less energy than laser cutting.

– Works for 120–300 µm wafers (ideal for PERC, TOPCon, HJT cells).

|

Parameter |

Diamond Wire Saw |

Slurry Saw |

Laser Cutting |

|

Cutting Speed |

10–25 m/s |

0.5–1 m/s |

5–10 m/s |

|

Kerf Loss |

100–150 µm |

180–250 µm |

30–50 µm |

|

Surface Quality |

Excellent |

Poor |

Good (but HAZ) |

|

Operating Cost |

Low |

Medium |

High |

|

Best For |

Mass production |

Legacy use |

Thin wafers |

Conclusion: Diamond wire saw cutting is the best balance of speed, cost, and quality for solar wafer production.

If you have any question, please contact us