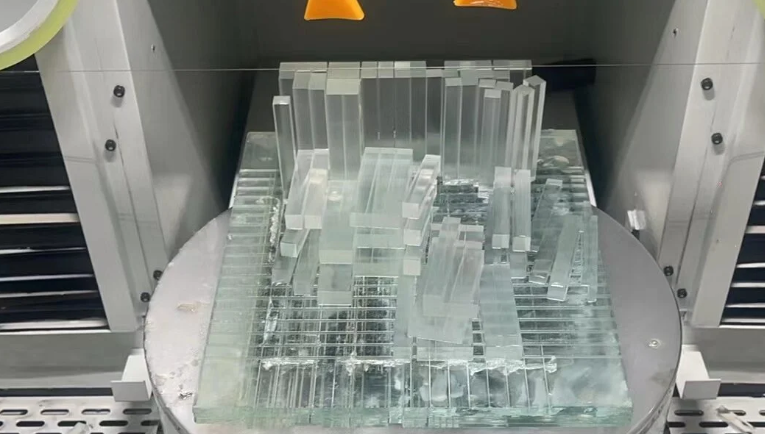

In the demanding field of optical manufacturing, the quality of a cut can determine the success of an entire optical system. Traditional cutting methods often introduce micro-cracks, subsurface damage, and edge chipping that compromise optical performance. Our solution? The ESG200 and ESG400 Diamond Wire Saw Cutting Machines – engineered from the ground up to address the unique challenges of cutting optical glasses, crystals, and advanced ceramics.

These machines represent a leap forward in precision cutting technology, incorporating specialized features that ensure crack-free results, exceptional edge quality, and unparalleled dimensional accuracy. Whether you’re working on camera lens array dicing, optical filter manufacturing, or precision components for aerospace and medical devices, the ESG series delivers the reliability and precision that modern optical applications demand.

A common question we receive is: what’s the difference between the ESG200 and ESG400 models? Both machines share the same advanced technological core and are designed with identical precision capabilities. The primary difference lies in their capacity:

In essence, you can select the model that best fits your workpiece size requirements without compromising on any of the critical precision features. Both are equipped with our proprietary Triple-Motion Cutting System and advanced Crystal Orientation Alignment capabilities.

What truly sets the ESG series apart from conventional diamond wire saws is its sophisticated approach to motion control. We’ve integrated three independent adjustment systems that work in harmony to optimize every cut.

The Pitch Adjustment function allows operators to precisely set the angle at which the diamond wire contacts the workpiece. This is crucial for:

During a cut, a stationary wire can develop a groove in the material, leading to uneven stress and potential deviation. Our Oscillating Cutting function moves the wire back and forth along its own path. This delivers critical benefits:

For cutting thick or large-diameter materials, maintaining perpendicularity and straightness is a major challenge. The Horizontal Swing Cutting function swings the entire wire loop assembly in a controlled arc during the cutting process. This advanced capability ensures:

Together, these three functions work synergistically to maximize cutting accuracy, improve surface integrity, and boost overall productivity.

For many optical and semiconductor applications, the crystallographic orientation of a material is as critical as its physical dimensions. The ESG series can be equipped with an optional integrated system for complete Crystal Phase Analysis and Orientation Finding. This system enables:

This feature is indispensable for manufacturing laser crystals, nonlinear optical components, and substrates where performance is directly tied to crystal orientation.

The ESG200 and ESG400 Diamond Wire Saw Cutting Machines are more than just tools; they are comprehensive solutions for the most challenging optical manufacturing problems. By integrating advanced motion control with optional crystallographic analysis, we provide a level of precision, efficiency, and reliability that was previously unattainable.

Ready to experience the future of optical glass cutting? Contact our team of engineering experts today to discuss your specific application requirements and discover how the ESG series can transform your production process, improve yields, and deliver superior quality components.

If you have any question, please contact us